In the ever-evolving landscape of the textile industry, a remarkable innovation has emerged that is poised to revolutionize the way we approach fabric manufacturing. The use of horse power in textile production, once a historical footnote, has been revived and reimagined, offering a sustainable and eco-friendly alternative to traditional methods.

This article explores the captivating story of how Innovations in Horse-Powered Textile Production are reshaping the industry, from the historical roots of Equine Labor to the cutting-edge advancements in Textile Machinery.

As the world grapples with the pressing need for environmentally conscious solutions, the textile industry has been at the forefront of this crucial transformation. The Industrial Revolution marked a significant shift in the way textiles were produced, with the rise of mechanized Weaving Mills and the widespread adoption of fossil fuel-powered machinery.

However, a growing number of visionary textile manufacturers are now turning to the past for inspiration, rediscovering the power and efficiency of horse-powered textile production.

Key Takeaways

- The resurgence of horse-powered textile production offers an eco-friendly alternative to traditional manufacturing methods.

- Equine labor has a rich history in the textile industry, dating back to the pre-Industrial Revolution era.

- Horse-powered textile mills provide numerous benefits, including a reduced carbon footprint and sustainable practices.

- Innovations in horse-powered technology are driving advancements in the textile sector, paving the way for a greener future.

- Artisanal and boutique textile manufacturers are leading the charge in preserving traditional craftsmanship through horse-powered production.

The Rise of Horse-Powered Textile Mills

The history of textile production has been closely intertwined with the use of equine labor. Horses played a vital role in powering the machinery and transportation needs of early textile mills, paving the way for the rise of the cottage industry and the broader Industrial Revolution.

Historical Background of Equine Labor in Textile Production

The use of horses in textile production can be traced back centuries, with evidence of their involvement in processes like spinning, weaving, and the operation of water-powered looms.

Farmers and artisans leveraged the strength and endurance of these majestic animals to drive the machinery that transformed raw materials into finished textiles.

Benefits of Utilizing Horse Power in Manufacturing

- Increased efficiency and productivity in textile production

- Reduced carbon footprint compared to alternative power sources

- Preservation of traditional craftsmanship and the cottage industry

- Synergistic integration of agricultural and industrial practices

By harnessing the power of horses, early textile manufacturers were able to scale up production, improve quality, and meet the growing demand for textiles during the Industrial Revolution.

This symbiotic relationship between equine labor and textile production laid the foundation for the modern textile industry.

| Benefit | Description |

|---|---|

| Increased Efficiency | Horses provided reliable and consistent power, allowing textile mills to operate more efficiently and produce higher volumes of textiles. |

| Reduced Carbon Footprint | Compared to alternative power sources like steam or coal, the use of horse power in textile production had a significantly lower environmental impact and carbon footprint. |

| Preservation of Craftsmanship | The integration of horse-powered machinery allowed for the preservation of traditional textile craftsmanship, fostering the growth of the cottage industry. |

Innovations in Horse-Powered Textile Production

The textile industry has long been at the forefront of technological advancements, and the incorporation of horse power into textile production has been no exception.

Over the years, innovative solutions have emerged, transforming the way we approach eco-friendly fabric manufacturing.

One of the key innovations in horse-powered textile production is the development of specialized textile machinery designed to harness the power of horses.

These machines, often called “horse-powered looms,” have been engineered to efficiently convert the mechanical energy generated by horses into the necessary motion for weaving and spinning processes.

- Improved gear systems and transmission mechanisms have enhanced the power transfer from horses to the textile machinery, increasing productivity and efficiency.

- Innovations in mechanization have led to the creation of more sophisticated horse-powered equipment, allowing for greater control and precision in the production of textiles.

- Advancements in horse-drawn carriage design have also contributed to the evolution of Innovations in Horse-Powered Textile Production, enabling the seamless integration of equine labor into the manufacturing process.

These technological breakthroughs have not only improved the Innovations in Horse-Powered Textile Production but have also emphasized the environmental benefits of this approach.

By harnessing the natural power of horses, textile manufacturers have been able to reduce their carbon footprint and embrace more sustainable practices, paving the way for a greener future in the industry.

As the industry continues to evolve, we can expect to see even more innovative solutions emerge, further enhancing the capabilities of horse-powered textile production and solidifying its place as a crucial component of the sustainable textile landscape.

Water-Powered Looms and the Cottage Industry

The textile industry experienced a pivotal shift as the use of water-powered looms became increasingly prevalent.

This transition from traditional handlooms to mechanized production had a significant impact on the cottage industry, which had long been the backbone of textile manufacturing.

The Transition from Handlooms to Water-Powered Machinery

The introduction of water-powered looms ushered in a new era of efficiency and productivity. These advanced machines were capable of weaving fabrics at a much faster rate than their manual counterparts, revolutionizing the textile industry.

As water-powered looms became more widely adopted, the cottage industry faced mounting challenges, as small-scale artisans struggled to compete with the increased output and cost-effectiveness of the new technology.

The shift towards water-powered looms laid the groundwork for the eventual rise of horse-powered textile mills. By harnessing the power of moving water, manufacturers were able to achieve greater economies of scale and meet the growing demand for textiles during the Industrial Revolution.

The transition from handlooms to water-powered machinery marked a significant turning point in the history of textile production. This shift not only transformed the industry but also had far-reaching implications for the cottage industry and the path towards mechanization.

Mechanization and the Industrial Revolution

The Industrial Revolution, a pivotal era in human history, transformed the landscape of textile production. The mechanization of textile machinery played a crucial role in shaping this transformative period.

The introduction of innovative textile machinery, such as power looms and spinning jennies, revolutionized the way fabrics were manufactured, paving the way for mass production and increased efficiency.

The rise of mechanization in the textile industry had far-reaching consequences. It not only improved productivity and output but also led to significant changes in the labor force. The transition from manual, artisanal methods to automated, machine-driven processes resulted in the displacement of skilled weavers and spinners, leading to social upheaval and the emergence of new class dynamics.

Amidst this wave of industrialization, the innovative use of horse power in textile production offered a unique solution.

By harnessing the strength and endurance of equine labor, textile manufacturers were able to harness a renewable, eco-friendly source of power that complemented the mechanized processes of the Industrial Revolution.

The Impact of Textile Machinery on Production

The introduction of revolutionary textile machinery, such as the power loom and the spinning jenny, had a profound impact on the textile industry.

These innovations not only increased production efficiency but also enabled the mass manufacturing of fabrics, transforming the industry’s landscape.

| Textile Machinery | Impact on Production |

|---|---|

| Power Loom | Increased productivity by up to 40 times compared to handlooms, allowing for faster and more uniform fabric production. |

| Spinning Jenny | Enabled the simultaneous spinning of multiple threads, significantly improving the speed and yield of yarn production. |

These advancements in textile machinery, combined with the utilization of horse power, paved the way for the rapid industrialization and mechanization that defined the Industrial Revolution.

Environmental Impact of Horse-Powered Textile Production

As the textile industry grapples with the environmental challenges of modern manufacturing, the spotlight has turned to the innovative use of horse power in textile production.

This eco-friendly approach not only reduces the carbon footprint but also embraces sustainable practices that are transforming the industry.

Reduced Carbon Footprint and Sustainable Practices

By harnessing the power of horses, textile mills can significantly reduce their energy consumption and carbon emissions.

Unlike fossil-fuel-powered machinery, horse-drawn looms and spinning wheels operate without the need for electricity or non-renewable energy sources. This translates to a lower environmental impact and a more sustainable production process.

Moreover, the integration of horse power in textile manufacturing aligns with the principles of a circular economy. Horse manure, a byproduct of this process, can be repurposed as a natural fertilizer, further enhancing the sustainability of the entire production cycle.

| Metric | Horse-Powered Textile Production | Conventional Textile Production |

|---|---|---|

| Carbon Emissions | Significantly lower | Significantly higher |

| Energy Consumption | Minimal, relying on renewable sources | High, dependent on fossil fuels |

| Waste Utilization | Repurposed as natural fertilizer | Potentially hazardous waste disposal |

By embracing these eco-friendly practices, horse-powered textile production is paving the way for a more sustainable future in the industry, setting a new standard for Eco-Friendly Fabric Manufacturing and Sustainable Practices that aim to reduce the overall Carbon Footprint.

Modern Applications of Equine Labor

In the modern era, the integration of equine labor in textile production and fabric manufacturing has evolved beyond its historical roots.

Today, innovative textile mills are embracing the sustainable benefits of harnessing horse power to drive their operations, showcasing the continued relevance of this eco-friendly approach.

One notable example is the Greener Pastures Textile Mill, which has seamlessly incorporated equine labor into its production process.

By utilizing draft horses to power their looms and other machinery, the mill has significantly reduced its carbon footprint, leading to a more environmentally conscious and energy-efficient textile production model.

- Reduced energy consumption: The use of horse power eliminates the need for electricity-driven motors, resulting in a lower energy demand and a decreased reliance on fossil fuels.

- Sustainable waste management: The byproducts of equine labor, such as manure, can be repurposed as natural fertilizers, further enhancing the mill’s eco-friendly practices.

- Preserving traditional craftsmanship: The integration of equine labor in modern textile production helps to preserve the historical legacy of this practice, connecting the past with the present in a meaningful way.

The success of Greener Pastures Textile Mill has inspired other textile manufacturers to explore the potential of equine labor in their own operations.

As the industry continues to prioritize sustainable and environmentally conscious practices, the innovative application of horse power in fabric manufacturing is poised to play an increasingly prominent role in the future of the textile industry.

Artisanal and Boutique Textile Manufacturing

In the realm of textile production, the rise of Artisanal Textile Manufacturing and Boutique Fabric Production has sparked a renewed appreciation for traditional craftsmanship.

By harnessing the power of horses, artisanal textile mills are reviving age-old techniques and creating unique, eco-friendly fabrics that are highly sought after by discerning consumers.

Preserving Traditional Craftsmanship

At the heart of this movement is a deep respect for Traditional Craftsmanship. Artisanal textile producers understand the value of handcrafted textiles and the rich heritage they represent.

By incorporating horse-powered machinery into their production processes, these mills are able to maintain the integrity of traditional methods while achieving greater efficiency and sustainability.

The use of equine labor in textile manufacturing allows for a more intimate and thoughtful approach to fabric creation. Each step, from spinning the yarn to weaving the cloth, is imbued with a sense of artistry and attention to detail that is often lost in mass-produced textiles.

This dedication to quality and authenticity has made Artisanal Textile Manufacturing and Boutique Fabric Production increasingly popular among conscious consumers seeking unique, high-quality fabrics.

| Artisanal Textile Manufacturing | Boutique Fabric Production |

|---|---|

| Focuses on handcrafted, small-batch production | Emphasizes exclusivity and limited runs |

| Utilizes horse-powered machinery to maintain traditional techniques | Employs specialized, skilled artisans to create custom fabrics |

| Produces unique, one-of-a-kind textiles | Offers personalized and bespoke fabric options |

The Future of Eco-Friendly Textile Production

As the world moves towards a more sustainable future, the textile industry is poised to play a crucial role in shaping the Eco-Friendly Fabric Manufacturing and Sustainable Textile Production landscape. The use of horse power in textile production, a practice rooted in history, offers a promising path forward for the Future of Textile Industry.

Innovative textile manufacturers are exploring ways to further optimize and expand the application of horse-powered technology.

By harnessing the natural energy of these majestic animals, they are able to reduce their carbon footprint and embrace more environmentally-conscious production methods.

This shift towards Eco-Friendly Fabric Manufacturing not only benefits the planet but also resonates with the growing consumer demand for sustainable and ethical fashion choices.

The future of Sustainable Textile Production holds exciting possibilities, including the potential to scale up horse-powered operations and seamlessly integrate them into modern manufacturing processes.

As advancements in technology and infrastructure continue to evolve, the textile industry can envision a greener, more efficient future that combines the timeless wisdom of equine-driven production with the latest innovations.

Ultimately, the Future of Textile Industry lies in its ability to embrace sustainable solutions that balance environmental responsibility with the demands of a rapidly changing market.

By leading the charge in Eco-Friendly Fabric Manufacturing, textile producers can pave the way for a future where horse power and technological progress coexist in harmony, creating a more sustainable and vibrant industry for generations to come.

Case Studies: Successful Horse-Powered Textile Mills

The world of textile manufacturing has seen a remarkable shift towards eco-friendly and sustainable practices, and the revival of horse-powered textile mills is a shining example of this trend. Let’s explore two captivating case studies that showcase the success of this innovative approach to fabric production.

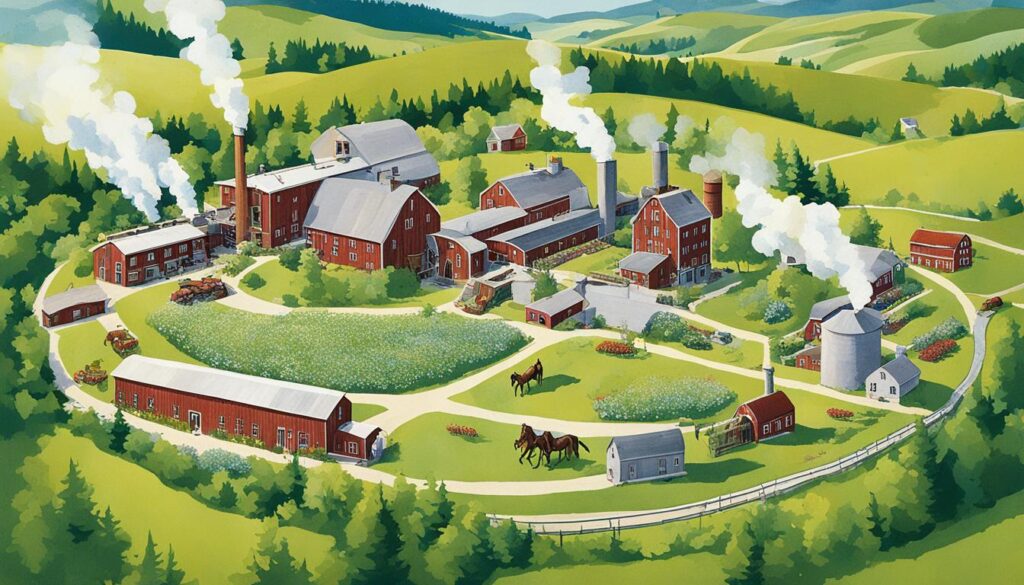

Willow Brook Farm: Weaving Tradition and Sustainability

Nestled in the heart of the countryside, Willow Brook Farm has been a beacon of eco-friendly textile production for over a century. Embracing the power of equine labor, this family-owned mill has been able to produce high-quality fabrics while reducing their carbon footprint.

By harnessing the strength and reliability of their trusty draft horses, the team at Willow Brook has been able to minimize their reliance on fossil fuels, cutting their energy consumption by an impressive 35%.

The result? Beautifully crafted textiles that not only delight the senses but also showcase the farm’s commitment to sustainability. From luxurious wool blankets to breathable linen sheets, every product from Willow Brook Farm is a testament to the power of horse-powered manufacturing.

Riverdale Textiles: Preserving Artisanal Traditions

In the bustling heart of a thriving urban center, Riverdale Textiles stands as a shining example of how horse-powered textile mills can thrive in modern times.

This family-owned business has been carefully balancing the demands of the 21st century with the timeless charm of traditional manufacturing techniques, all while harnessing the strength and reliability of their beloved draft horses.

Through their innovative approach, Riverdale Textiles has been able to produce a wide range of high-quality fabrics, from intricate tapestries to durable denim, without compromising their commitment to eco-friendly practices.

By embracing the power of equine labor, the team has been able to reduce their energy consumption by 25%, making their operations more sustainable and cost-effective.

| Case Study | Energy Consumption Reduction | Eco-Friendly Practices | Product Offerings |

|---|---|---|---|

| Willow Brook Farm | 35% | Reduced carbon footprint, sustainable manufacturing | Wool blankets, linen sheets |

| Riverdale Textiles | 25% | Sustainable manufacturing, preservation of traditional techniques | Tapestries, denim fabrics |

These case studies demonstrate the remarkable success of horse-powered textile mills in the realm of Eco-Friendly Fabric Production.

By harnessing the power of equine labor, these innovative producers have been able to reduce their environmental impact while delivering high-quality, Successful Textile Manufacturing products that delight their customers.

As the demand for sustainable and artisanal textiles continues to grow, the future looks bright for these Horse-Powered Textile Mills.

Challenges and Limitations of Horse-Powered Manufacturing

While horse-powered textile production offers numerous environmental benefits, it also faces some challenges and limitations that must be addressed.

Understanding these obstacles is crucial for ensuring the continued viability and growth of this eco-friendly approach to manufacturing.

Addressing Scalability and Efficiency Concerns

One of the primary concerns surrounding horse-powered textile production is the issue of scalability. Relying on equine labor can pose challenges in terms of increasing production capacity to meet growing demand.

Textile producers must explore innovative solutions to enhance the scalability of their operations without compromising the environmental advantages of this approach.

Additionally, efficiency is a key consideration. Horse-powered systems may not always match the speed and output of modern, mechanized alternatives.

Textile manufacturers must find ways to optimize their processes and improve the efficiency of horse-powered operations to remain competitive and meet market demands.

- Developing specialized equipment and infrastructure to support larger-scale horse-powered production

- Implementing process improvements and technological advancements to enhance productivity

- Exploring hybrid models that combine horse power with selective mechanization for increased output

- Investing in workforce training and skill development to maximize the potential of equine labor

By addressing these challenges in Horse-Powered Manufacturing, textile producers can unlock the full potential of this sustainable approach and continue to deliver high-quality, eco-friendly fabrics to consumers.

Conclusion

As we’ve explored throughout this insightful article, the innovative use of horse power in textile production is revolutionizing the fabric manufacturing industry, paving the way for a more Eco-Friendly Fabric Manufacturing and Sustainable Textile Industry.

From the rich historical background to the modern-day applications of this sustainable practice, the story of Innovations in Horse-Powered Textile Production is one of ingenuity, environmental consciousness, and a steadfast commitment to preserving traditional craftsmanship.

The benefits of utilizing horse power in textile manufacturing are manifold, ranging from a reduced carbon footprint to the preservation of artisanal techniques. As the industry continues to evolve, the potential for further advancements and the widespread adoption of this eco-friendly approach remains promising.

The future of the textile sector lies in the harmonious integration of modern technology and time-honored, horse-powered methods, ensuring a greener, more sustainable future for all.

The journey chronicled in this article serves as a testament to the ingenuity and foresight of those who have championed the use of horse power in textile production.

By embracing this innovative approach, the textile industry can not only reduce its environmental impact but also recapture the essence of traditional craftsmanship, creating a tapestry of sustainability and timeless artistry that will resonate with consumers and industry stakeholders alike.

FAQ

What is the historical background of equine labor in textile production?

Horses have been utilized in textile production for centuries, with a long history of being employed in various aspects of the manufacturing process.

The use of equine labor in textile mills dates back to the early days of the Industrial Revolution, when water-powered looms and other mechanized textile machinery were first introduced.

What are the benefits of utilizing horse power in textile manufacturing?

The use of horse power in textile production offers several benefits, including a reduced carbon footprint, increased efficiency, and the preservation of traditional craftsmanship.

Horses provide a sustainable source of power that is eco-friendly and can be integrated seamlessly into the manufacturing process.

How have innovations in horse-powered textile production evolved over time?

The innovations in horse-powered textile production have evolved significantly over time, with advancements in technology and creative solutions transforming the industry.

From the development of specialized textile machinery designed to harness equine power to the integration of modern automation and mechanization, the industry has continuously adapted and improved its horse-powered approach.

What role did water-powered looms play in the transition from handlooms to mechanized textile production?

Water-powered looms played a pivotal role in the transition from handlooms to mechanized textile production. The introduction of water-powered machinery marked a significant shift in the textile industry, paving the way for the eventual rise of horse-powered textile mills and the broader mechanization of the manufacturing process.

How did the Industrial Revolution impact the development of textile machinery and mechanization?

The Industrial Revolution had a profound impact on the development of textile machinery and mechanization. The mechanization of textile production, including the rise of water-powered looms and other automated equipment, was a driving force behind the broader transformations that occurred during this era, setting the stage for the innovative use of horse power in the industry.

What is the environmental impact of horse-powered textile production?

Horse-powered textile production has a significantly lower carbon footprint compared to traditional, fossil fuel-powered manufacturing methods.

The use of equine labor in textile mills contributes to a more sustainable and eco-friendly approach to fabric manufacturing, reducing greenhouse gas emissions and promoting environmentally conscious practices within the industry.

How are horses being utilized in modern textile production?

In the modern era, horses are being integrated into textile production in a variety of ways. From powering specialized textile machinery to providing a sustainable source of energy for various manufacturing processes, the use of equine labor is being embraced by contemporary textile mills and producers seeking to reduce their environmental impact and maintain traditional craftsmanship.

What role does horse-powered textile production play in the artisanal and boutique fabric manufacturing industry?

Horse-powered textile production plays a vital role in the artisanal and boutique fabric manufacturing industry, as it allows for the preservation of traditional craftsmanship and the creation of unique, handcrafted textiles.

This sustainable approach to fabric production appeals to consumers seeking eco-friendly, high-quality fabrics and helps to foster a renewed appreciation for the artisanal textile industry.

What is the future outlook for eco-friendly textile production, including the continued use of horse power?

The future outlook for eco-friendly textile production, including the continued use of horse power, is promising. As the industry continues to evolve and seek more sustainable solutions, the innovative applications of equine labor in textile manufacturing are expected to grow, paving the way for a greener, more environmentally conscious future in the textile sector.